|

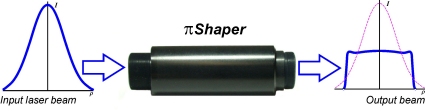

An idea of piShaper operation is illustrated

at the picture below. Gauss intensity distribution of TEMoo laser beam

is converted to a flat-top distribution (similar to a Greek letter

π) that stays invariable for a long distance.

Sure

the technology of energy conversion make it possible to create almost

arbitrary intensity distribution of output beam providing adaptation

to a particular application. However, very often just flat-top distribution

is required, that is why as a standard the piShaper provides

flat-top.

A main benefit from using piShaper is saving

of laser energy that is very important in many laser applications, especially

in material processing. The problem is that Gauss intensity distribution

isn't an optimum one in many cases. For example, while materials treating

a great part of energy concentrated far from a middle of TEMoo laser

beam is not used to get a proper treating effect, most often it is considered

as a loss of energy. From this point of view evaluation of the efficiency

of using laser energy has a great importance.

As a first approach it could be done with taking into account

geometrical issues only, without effects accompanying laser treatment

of materials like burning, etc. At a figure below one can see Gauss

intensity distribution in a section of laser beam where Ih is a level

of energy when an effect of material treatment happens. "The energy

figure" of laser beam has three parts:

- E1 - an apex

of Gauss is an excess of energy over the working level Ih,

- E2 - "tails"

of Gauss that almost always are losses of energy, and

- E3 - effective

"cylinder" of energy.

Results of calculations for "parts of energy" are presented

at right figure.

These

results seem to be very interesting. The unconditional energy loss E2,

"tails", can reach very high level, for example, if a working energy

level is a half of maximum (very often just this level is considered

as a working one) the energy losses are 50% of full laser beam energy!

In case of laser technologies of treatment of thin films

of material the energy part E1, "apex of Gauss", is also considered

as a loss of energy since this part exceeds the working energy level

Ih, thus both energy parts E1 and E2 represent losses.

Sum of losses E1 + E2 is shown as a graph at the diagram

as well; minimum of this function is 0,63. In other words, when treating

of thin films in the best case "only" 63% of energy is lost and 37%

is effective!

Sure, this is geometrical interpretation only, however

this approach makes it possible to evaluate amount of losses of laser

radiation, they could reach, sometimes, a half of total laser energy!

While applying technologies of beam shaping it is possible to improve

substantially the efficiency of using the laser energy, as well as to

reach some additional effects of laser materials treatment.

Full

publication about energy saving is here(PDF, 141 KB).

|